Part Two of the Lightning Ridge trip (remember to click on any of the photos to see a larger version):

Mining techniques are almost as diverse as the people that do it – from full hand work similar to when the mining first started in the area to some very expensive underground gear along with large open cuts. This photo shows a large treatment plant.

Mining techniques are almost as diverse as the people that do it – from full hand work similar to when the mining first started in the area to some very expensive underground gear along with large open cuts. This photo shows a large treatment plant.

Traditionally, opals have been mined underground and this is still common in the area. However, open cut mining has also been used. In this photograph, you can see where the open cut has exposed some small mine shafts in the centre-right of the image (visible through the wire fence).

Traditionally, opals have been mined underground and this is still common in the area. However, open cut mining has also been used. In this photograph, you can see where the open cut has exposed some small mine shafts in the centre-right of the image (visible through the wire fence).

We arranged a visit below ground with an opal mining acquaintance from my home town of Glen Innes. This miner who was kind enough to spare his time on us was up there with good underground gear, although he explained there is much better on the field. His mine was about 20km west of the Ridge – crossing a huge black soil flat I thought we would never find a mine. The flat is called The Lake and although it is farmed, our guides Chris and Bea told us that locals have water skied on the vast open area in wet times. Suddenly the more familiar camps came into view and I was glad I had a guide as, unlike at the Ridge, the car door signs were nowhere to be seen. Just what seemed like hundreds of tracks all leading somewhere no doubt very important to those that use them.

Once we got to the camp, the typical friendly, laidback nature was evident again. After several weeks mining, these hard working folks just wanted to talk – all interesting stuff so we listened and learnt. The camp was very clean and well built with two large caravans joined by a steel shed between them. After a cuppa, it was boots on and get to work which was a couple of miles away.

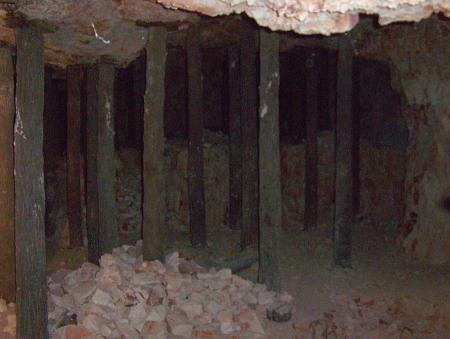

These areas have been worked for a long time and as we pulled up at the mine we were shown the basic layout of the underground workings below us. Down below at about 30 feet, there was an area of around 50 x 30 metres (see photo above right) that had been completely removed and propped, with another deeper level below (somewhat unusual as most is just narrow shafts) and tunnels that went all over the place, some linking to each other and some not. It’s quite easy to get lost in some of these networks and Chris told of some areas where you can walk underground for around 2 miles without turning around.

Divining the opal – we do this all the time with our sapphire and it’s got a strong following out there too. Same technique with some using rusty fencing wire like me and others using bought ones (made by a “secret method”). This photo shows David having a go with the divining wires after having been asked by a local to check his claim for him. Chris had painted marks up on top showing where he thinks a run goes and coupled with small pilot test holes to check for the location and more importantly check that the roof area is good and strong for safety.

Divining the opal – we do this all the time with our sapphire and it’s got a strong following out there too. Same technique with some using rusty fencing wire like me and others using bought ones (made by a “secret method”). This photo shows David having a go with the divining wires after having been asked by a local to check his claim for him. Chris had painted marks up on top showing where he thinks a run goes and coupled with small pilot test holes to check for the location and more importantly check that the roof area is good and strong for safety.

Most of the mining is done underground with hydraulic diggers and vacuum pumps or suckers to lift the rock and dirt up to ground level into the trucks. Here Chris is seen scraping the rocks towards the suction pipe – any pieces that wont fit up the 10″ pipe need to be broken and much of the product dragged by hand into the suction. Although this type of mining is mechanised, it still involves very hard work.

The rock is loaded into a waiting truck and then taken for processing in an agitator – cement mixing trucks are used for this job. Here is a line up of agitators (this photo shows only half the mixers on this site). Chris aims for one truck load per day which is usually around 4-5hrs digging.

The rock is loaded into a waiting truck and then taken for processing in an agitator – cement mixing trucks are used for this job. Here is a line up of agitators (this photo shows only half the mixers on this site). Chris aims for one truck load per day which is usually around 4-5hrs digging.

The truck load of rock and dirt are fed up a conveyor (more hand work as although they use tippers, the larger rocks block the trapdoors). This is then agitated for 8 hours on average to break up lumps and wear them away while feeding water into it all the time to remove the silt. Artesian water is used as the water supply, with an open bath on site for the workers, although there is another hidden bath most use (this is hot and dirty work so an on-site bathtub is handy). On completion of the washing, the ore that remains is fed into a tray where any opal or possible opal bearing pieces are simply hand picked.

The price for Opal is all over the place with small attractive pieces ranging from around $20/ct to tens of thousands per carat for that one special stone. It’s the kind of town that lives on dreams and once someone hears that you are involved with mining (and perhaps a possible buyer), all sorts of people come up to you and produce bags of opal for you to consider.

I recommend anyone interested in a completely different way of life to visit Lightning Ridge one day. One important local tourist site is the natural Bore Baths where hot water straight from the Great Artesian Basin can soak away your aches and pains – mineral spa baths with hot water at 40 degrees Celcius free of charge anytime.

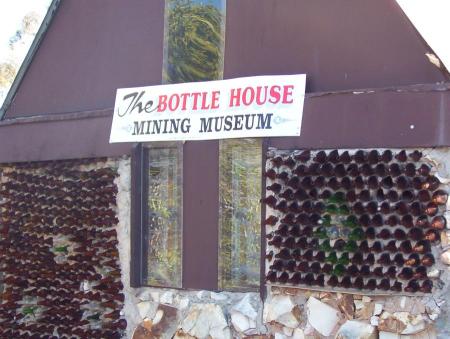

There are also two houses made from glass bottles and one we didn’t see made from tin cans. Lightning Ridge can get pretty hot in the summer so drinking all the beer in those bottles was probably not a difficult task for a thirsty miner. The photo on the right is a typical old miners cottage.

There are also two houses made from glass bottles and one we didn’t see made from tin cans. Lightning Ridge can get pretty hot in the summer so drinking all the beer in those bottles was probably not a difficult task for a thirsty miner. The photo on the right is a typical old miners cottage.

Hope you enjoyed this short story and photos about Lightning Ridge – we certainly enjoyed our trip out there. Back to work now – have just listed some great new sapphire rough and will now spend a little time looking through the opal rough I managed to get my hands on while out west.

cheers for now from Andrew (Aussie Sapphire)